Silica sol

Brief description

In order to improve the clarity of the product portfolio, Nouryon (formerly AkzoNobel Specialty Chemicals), manufacturer of silica sols Levasil® / Bindzil/ Cembinder, has decided to unite silica product lines under the single brand name:

Levasil® Colloidal Silica

Since June 1, 2016 products of Nouryon (formerly AkzoNobel Specialty Chemicals) are available under new product names. This has already been implemented in the following overviews. Please note that this is only a change of names - quality and characteristics of the products remain unchanged.

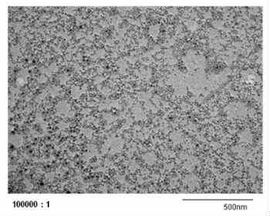

Silica sols are aqueous, solvent-free, low-odour, colloidal solutions of amorphous silicon dioxide (SiO2) with particle sizes from 5 nm to 100 nm.

Because of the special manufacturing process the silica comes in the form of free, non-crosslinked, single spherical particles that have a negative charge in anionic sols, which are stabilised by very small amounts of cations (typically sodium). This is in contrast with the cationic silica sols, which consist of cationic-charged silica sol particles through a specific chemical modification.

Typically, these preparations have a narrow particle size distribution, high density, low viscosity and no discernible separation tendency. In contrast to re-dispersed solids, silica sols manage without the use of auxiliaries such as dispersants, emulsifiers or thickening agents.

While the coarse silica sols present milky cloudy liquids, the finely particled silica sols from about 200 m²/g are relatively clear, opalescent liquids.

Brief information

Product group

Colloidal silicic acid / silica sols

Product name

LEVASIL®

Manufacturer

Nouryon (formerly AkzoNobel Specialty Chemicals)

Kurt Obermeier GmbH & Co. KG

Silica sols with a particle diameter greater than 15 nm

- Rather coarse, relatively inert types with a high active content

- Character of a reactive filler

- Dulling of surfaces, for example in the field of non-slip finishing of packaging materials

- Polishing agent in special polishing processes

Silica sols with a particle diameter of 11-15 nm

- Standard types with average particle sizes, reactivities and active contents

- Reactive binding agent components available for silicate and organic systems, particularly low-sodium types

- Component of refractory materials

- Setting accelerators for cementitious systems

- Thickening agents for gel batteries

Levasil® 200B/30 | ||

Levasil® CS30-125LS | ||

Silica sols with a particle diameter less than 10 nm

- Very finely particled sols with pronounced reactivity and low to medium active contents

- Typically, water-white, opalescent preparations

- Distinctly reaction-accelerating binding agent components for inorganic and organic preparations

- Hydrophilic modification of surfaces, e.g. for anti-fogging

- Special types for the paper industry

|

Special types for the coating and adhesive sectors:

Levasil® 300/30 ADH 06 and Levasil® 300/30 ADH 16

Application areas for silica sols

Foundries and steel sector

- For use as component of binding agents for

- precision casting using the shell process

- precision casting and artistic casting using the lost wax method

- coating of steel plates

- and as component of anti-corrosion coatings

Refractory sector

- Binding agent for ceramic and refractory materials such as ceramic fibres, glass fibres, etc.

- (Co-) Binding agent for ceramic materials and moulding compound

- Component of purely inorganic adhesive systems

Dental sector

- Component of investment materials

- Component of ceramic coatings

Chemical industry

- Modification of alkali silicates

- Component of anti-corrosion coatings

- Binding agent for the production of catalysts and granules

- Coating systems

- Modification of binding agents for improvement of:

- Adhesive strength

- Setting speed

- Scratch resistance and blocking resistance

- Improvement of water resistance and heat resistance

Paper industry

- Non-slip finishing of paper products such as paper bags, cardboard etc.

- Component of anti-wear coatings

Plastics industry

- Component of anti-wear coatings

- Component of scratch-resistant finishing for plastic surfaces

- Modification of binding agent systems, e.g. for cast films

Semiconductor technology / optical components

- Semiconductor technology / optical components

Coating systems / adhesives

- Adhesion improvement

- Setting acceleration

- Improvement of film hardness

- Improvement of blocking resistance, including early blocking resistance

- Improvement of film cohesion (e. g. for paving and PSA applications)

Textilsektor

- Components of products for non-slip finishing

- Additive for spin preparations

- Component of coating systems and impregnations

Building sector

- Binding agent for fire and heat protection applications

- Component of exterior paints and plasters

- Preparations of stone strengtheners

- Setting accelerators for cement-bonded systems

- Shotcrete

On request, we will gladly send you our current product documentation and samples for laboratory tests

Contact Persons

Authorized Representative Elke Dickel

Sales of Specialty Chemicals

+49 (0) 2751 / 524-155E-Mail-KontaktYour contact for

- Alkyl phosphates

- Iminodisuccinic acid (Baypure CX Koraplex)

- Silica sols (Levasil)

- Molecular sieves (zeolites)

- Phosphonic acids (Bayhibit)

- Polyaspartic acid (Baypure® DS, Koraplex)